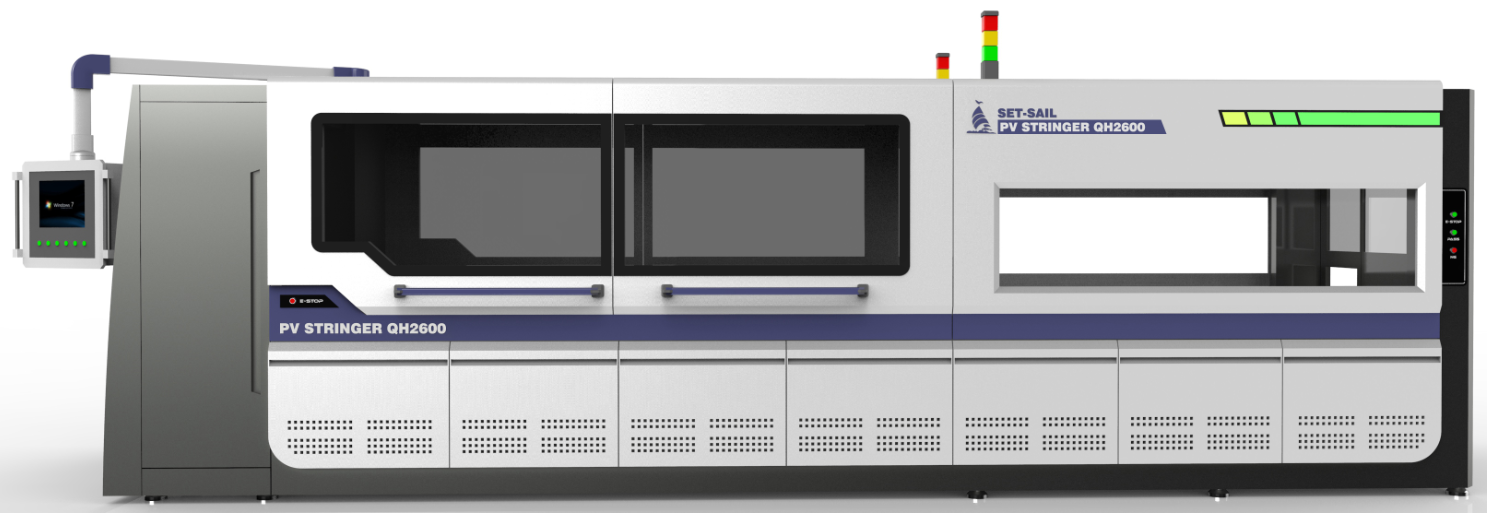

PV cell high-speed string welding machine

The QH2600 series dual-rail PV cell string welding machine has been innovatively designed according to domestic and foreign equipment on the market, and has applied for 5 utility model patents (patent pending). This equipment has the following advantages:

Vehicles can be adjusted according to customer products

The CCD visual inspection system implements high-precision defect detection and positioning, and uses EPSON four-axis robots to complete the classification, handling and positioning of battery cells

Originally created a flux spraying system to achieve clean and efficient requirements, saving product waste and environmental pollution

Infrared welding and flexible positioning pre-pressing device are used to achieve perfect welding. The welding temperature and power are controlled by closed loop and stepped temperature control system, which effectively reduces the fragmentation rate and defective rate of the cell